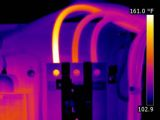

Infrared imaging allows apparent temperatures to be seen as gradient colors, with hotter spots displayed as brighter colors, and cooler (and wetter) spots displayed as darker colors. When a malfunctioning electrical component or connection is generating more heat than it should be, its apparent temperature will make it stand out right away when viewed through thermal imaging.

Infrared imaging allows apparent temperatures to be seen as gradient colors, with hotter spots displayed as brighter colors, and cooler (and wetter) spots displayed as darker colors. When a malfunctioning electrical component or connection is generating more heat than it should be, its apparent temperature will make it stand out right away when viewed through thermal imaging.During an inspection, electrical equipment, such as distribution panelboards, switch boards, contacts, transformers, receptacles, and service and control panels, can be examined through an IR camera. By viewing apparent temperature differences, inspectors can identify and document problems, such as loose connections and overloaded circuits, which are the most common causes of electrical fires. Other issues, such as transformer cooling problems, induced currents, arcing, and motor-winding faults, also become readily apparent.

Thermal imaging can detect electrical issues that include:

- excessively hot or loose connections;

- overloaded wiring;

- overloaded circuits;

- overloaded transformers;

- overloaded motors;

- arcing; and

- excessive harmonics.