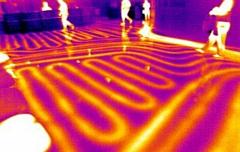

By viewing the different temperatures that appear in a room, IR cameras are handy tools for inspectors to show where heat could be escaping or where moisture is building up. When something is under zero degrees, it will offer an infrared radiation which cannot be seen by the naked eye but is easy to spot on thermal imaging. Without this tool, it would be much harder to locate problems but inspectors now have a helping hand and the key is to understand the data that it shows.

During an inspection, an IR camera will be used essentially as a scanner so will never come in contact with anything. When looking over a large area, this tool is fantastic because you can quickly spot problems and areas of interest. However, interpreting the data can be tough with no prior knowledge. When looking to find the energy radiating from an object, this will depend on the material’s emissivity. Ultimately, this can mean that thermal images are interpreted incorrectly.

When considering emissivity, this takes into account an object’s surface and the materials used for construction. With this in mind, higher emissivity comes from non-metals and opaque surfaces whereas lower emissivity can be found in shiny surfaces made from pure metals. Although low emissivity objects can be assessed with thermal imaging, care needs to be taken so that accurate results can be achieved. As an example, some reflected surfaces will be affected by a hot light bulb in the room. Without seeing the light bulb, it is easy to think that the area in question has a problem. As long as all factors are considered along with all angles within a room, accurate results can be achieved. If you need help with obtaining accurate results, there are now a number of charts that show emissivity within objects which can be superb to learn.